MINING

At Industrial Drive Service Inc., our mission is to empower the mining industry with reliable, high-performance automation and motion control solutions. We are committed to delivering innovative drive systems, expert support, and custom-engineered technologies that enhance safety, efficiency, and uptime in the world’s most demanding mining environments. Through 24/7 service, global reach, and a dedication to quality craftsmanship, we strive to be the trusted partner that keeps mining operations moving forward.

Solutions for the Mining Industry

Automation and Motion

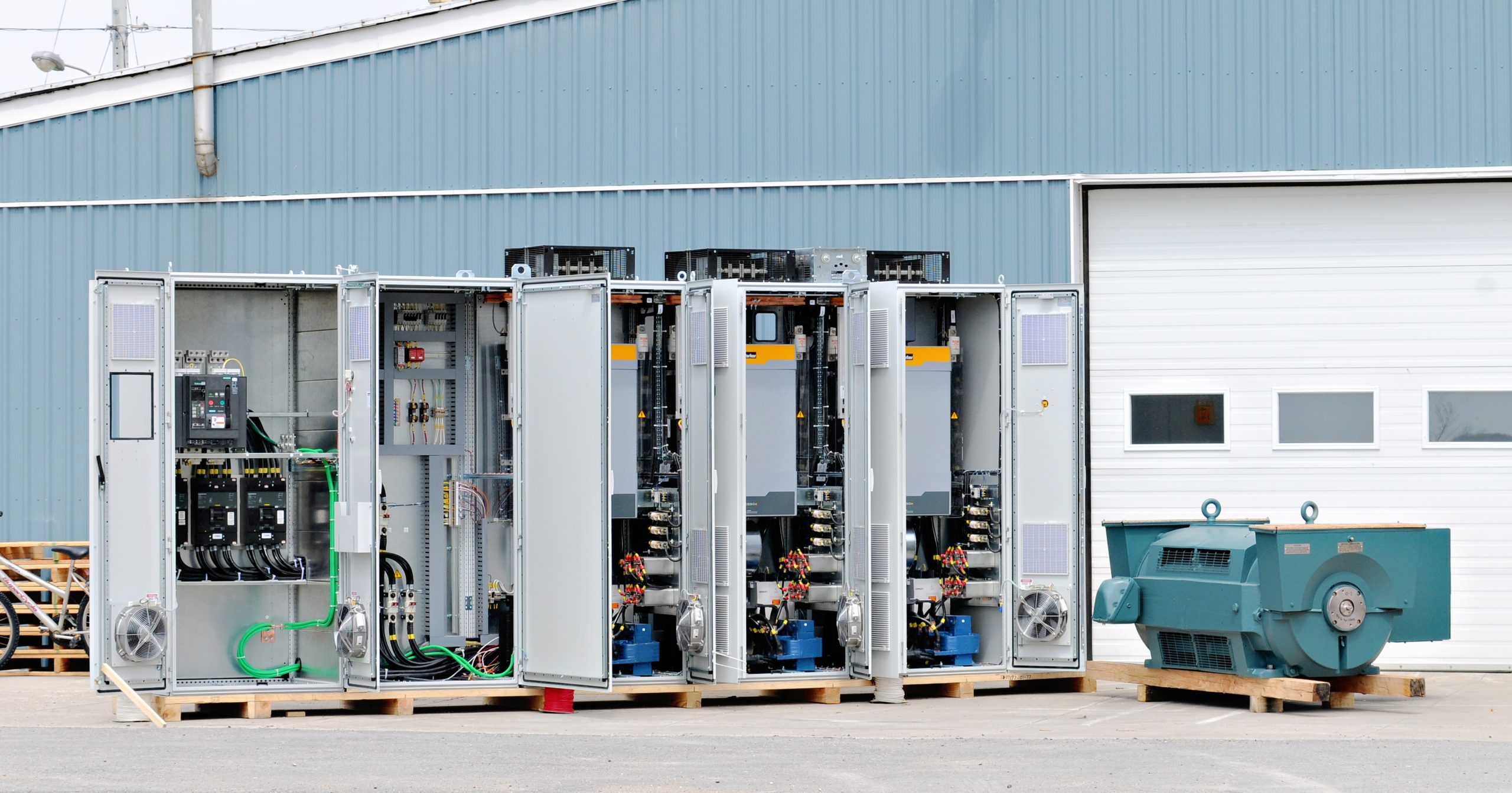

At our motion and automation solutions group, Key Solutions, motion control is at the core of what we do. Our specialized expertise in mining automation enables us to design, implement, and support precision control systems that drive critical equipment in the harshest underground and open-pit environments.

We deliver motion control solutions engineered for high-horsepower applications such as hoists, mills, and conveyors, with a focus on seamless integration, safety, and long-term reliability. Whether we’re retrofitting legacy DC motor hoist systems or commissioning new installations, IDS ensures exacting performance through our deep knowledge of load dynamics, torque control, and system synchronization.

Our engineers work with leading technologies—including Parker VFDs and Siemens motion control platforms—to provide advanced features such as closed-loop feedback, coordinated multi-axis movement, and remote diagnostics. Every system is tailored to the specific operational and environmental needs of the site.

With a CSA-certified panel shop, licensed electrical team, and 24/7 field support, IDS is a full-service motion control partner that mines can count on—from initial design through to long-term maintenance. Our solutions are powering operations across Canada, the USA, South America, and Africa, helping mining clients improve productivity, safety, and control where it matters most.

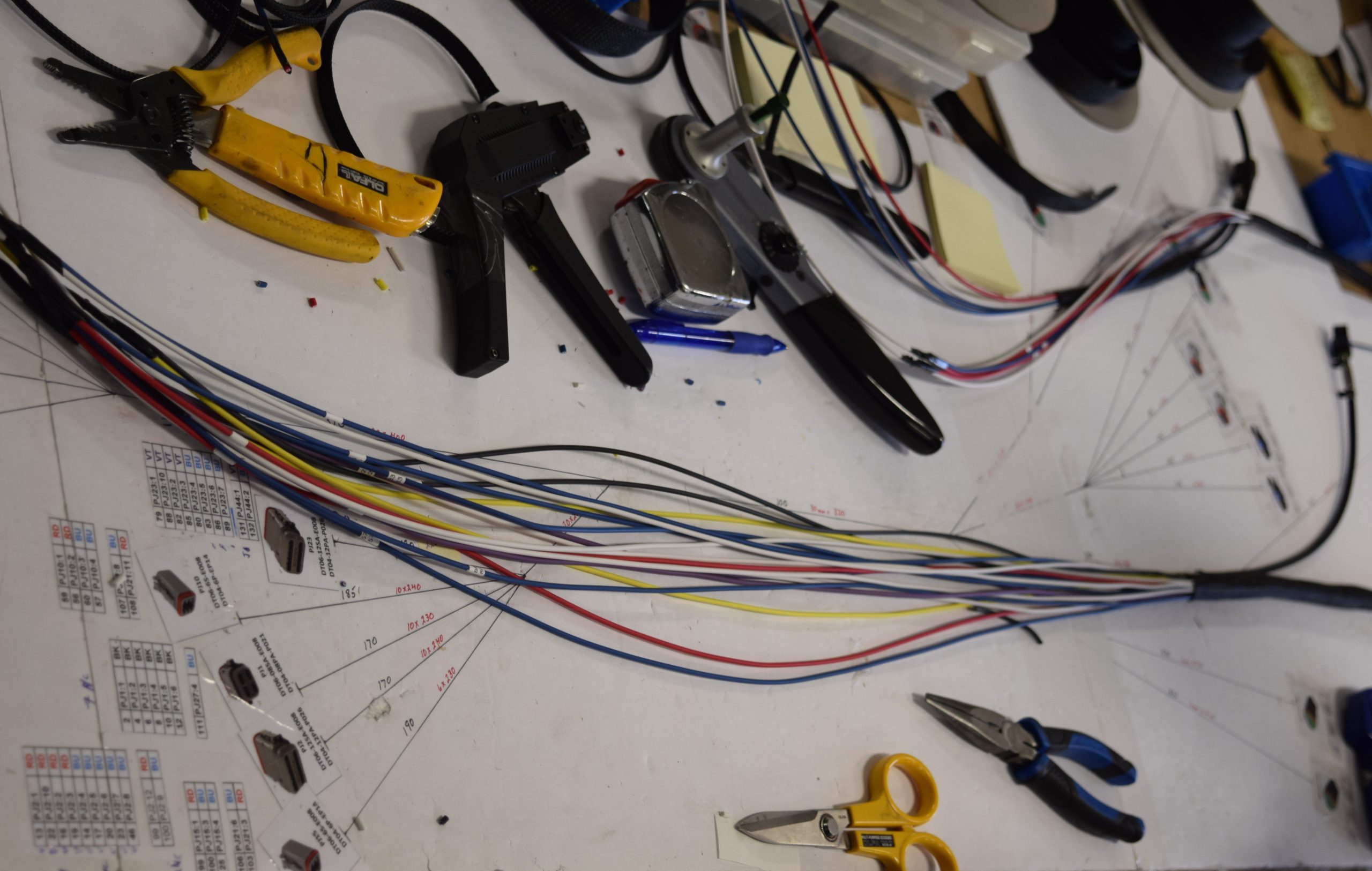

At IDS Harness, we design and manufacture high-quality wire harnesses built to withstand the extreme conditions of mining operations. Whether for mobile equipment, automation systems, or heavy machinery, our harnesses are engineered for durability, reliability, and ease of integration in both underground and open-pit environments.

Each harness is custom-built to client specifications and application needs—ensuring precise fit, optimal routing, and robust protection against abrasion, moisture, oil, vibration, and electrical interference. We use mining-grade components and materials, and our harnesses are assembled in-house to meet stringent quality and safety standards.

Our experienced team works closely with OEMs, maintenance teams, and engineering departments to provide:

-

Custom layouts and pinouts for specific equipment

-

Full documentation and labeling for simplified installation

-

Design support for harness upgrades and replacements

-

Rapid turnaround to support urgent field needs

From prototype development to production-scale manufacturing, IDS delivers rugged harness solutions that improve system reliability, minimize downtime, and reduce troubleshooting in the field. Our harnesses are in use throughout North America, South America, and Africa—supporting critical mining operations with dependable power and signal distribution every day.

Harness Assembly

Service & Repairs

Industrial Drive Service Inc. provides end-to-end service solutions that keep mining operations running efficiently, safely, and without costly interruptions. With deep technical expertise and a 24/7 response model, we support a wide range of electrical and automation systems critical to both underground and surface mining environments.

Our service offerings are designed to maximize uptime, improve system performance, and extend equipment life through proactive maintenance, expert troubleshooting, and smart system upgrades.

Our Mining Service Capabilities Include:

-

Field Service for Drive Systems: Rapid on-site support for troubleshooting, commissioning, and maintenance of low and medium-voltage drives, minimizing downtime in remote or high-demand environments.

-

In-House Drive Repairs: Professional bench repair and testing of drive systems in our facility, backed by manufacturer-level expertise and access to critical replacement parts.

-

Thermal Imaging & Diagnostics: Non-invasive thermal scanning to detect overheating components, identify potential failures, and ensure optimal system performance before problems occur.

-

Power Quality & Power Factor Monitoring: Real-time analysis and reporting to identify voltage imbalances, harmonic distortion, and low power factor—helping sites improve energy efficiency and reduce utility costs.

-

PLC Retrofits & Programming: Upgrades and modifications to existing PLC systems for enhanced control, safety, and integration with newer automation platforms. We support a wide range of PLC brands and specialize in seamless retrofits.

-

Data Monitoring & Reporting Systems: Implementation of real-time monitoring solutions for drive performance, energy usage, and operational data—empowering clients with actionable insights and predictive maintenance capabilities.

With responsive support teams, global field service reach, and proven expertise in drive technology and industrial automation, IDS is a trusted service partner for mining operations looking to protect their investments and optimize performance.