Agriculture

IDS offers numerous controls and automation solutions to the agricultural industry. Leveraging all of IDS’s business group, IDS AGRI functions as a vertical unit selling all our capabilities to agricultural applications.

IDS AGRI Provides The Following Services To Ag-related Customers:

Motion Control Solutions

- Through our Key Solutions unit, IDS can design, build and commission automation and motion control projects

- See more on our AgriPanel – a full controls system developed with farmers and grain handlers in mind

Power Factor Correction

- Many farms, grain handlers, mills, and greenhouses can benefit greatly through power factor correction

- Three-phase motors not on VFDs will typically cause a poor power factor, resulting in penalties and higher electricity bills from their utility

- Cos Phi expertise can determine ideal power factor correction method and sizing, and has been implemented in numerous grain handling systems.

Wire Harnessing

- MIDS works directly with numerous Agricultural OEMs to meet their wire harness and mobile control needs

- We produce wire harness assemblies built to our customer’s specifications and expectations. Wire harnessing from Industrial Drive Service combines the power of automation with the attention to detail that highly trained personnel provide.

Service & Repairs

- IDS offers 24/7 emergency service to agricultural customers

- We offer service, retrofits, preventative maintenance and more to our own systems and others

- Capable of working with a variety of Drive, PLC and HMI brands

Kongskilde Industries Grain Offerings

- IDS is now a representative for Kongskilde Industries and can source pneumatic conveyors, cleaners, components etc. for your grain needs

AgriPanel

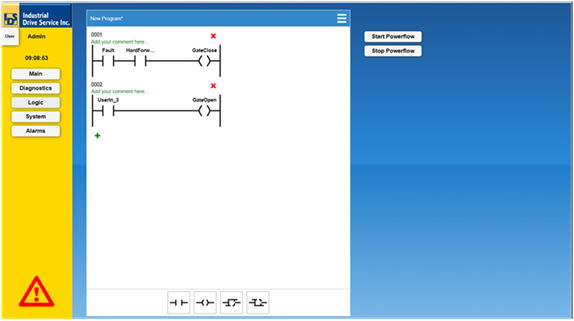

ired of your existing analog control panel that requires you to do everything from one place, and to know the correct sequence of motor starting? Interested in an automated grain control solution but scared of limited customization or high subscription costs? IDS has developed the AgriPanel – a means of providing farmers better insight, efficiency, control, and accessibility over their new or existing systems. The AgriPanel is an easy to install control system that is designed to adapt and grow as your farm does.

Farmers are not looking to change their entire method of operation, or to lose control of the equipment that they know best. An AgriPanel can be as simple as bringing manual control of grain equipment to outside of the control hut and accessible on any local device. Alternatively, it can be designed to be a complete and centralized automation solution for you farm and grain storage system.

Choose a system designed to grow with you.”

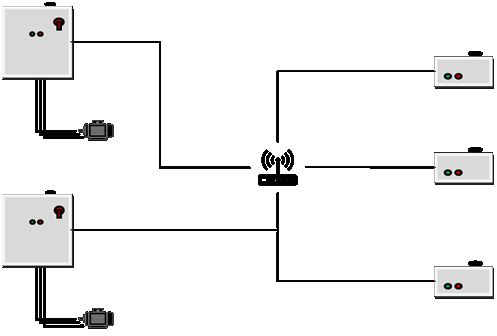

At IDS, we are able to link multiple AgriPanel products together to expand your system quickly, and without an interruption of your already placed system.

Each AgriPanel is customized to the specific application but with a consistent and well-considered framework. They can generally be grouped into the following categories:

Example Usage: Farm A needs to start, stop, and sequence its drag chain conveyor, bucket elevator, and two fans from outside its existing control hut. They also want alarm notifications if something isn’t operating typically. The AgriPanel Control helps reduce time spent training workers and starting up their system. It also allows them to schedule weekly fan intervals during winter months, saving them hassle and things to remember. With alarms and monitoring in place, they can reduce clean-up and damage significantly when one motor is overloaded compared to their previous manual controls.

Example Usage: Farm B has issues with the motors on their generator-powered grain storage system. Users are not consistent with their order and timing of starting them, and they struggle with overloading the generator, increased mechanical stress and clogging. By adding soft starters to just their drag chain and bucket elevators, The AgriPanel Engage system reduces troublesome and costly shut-downs of their grain system.

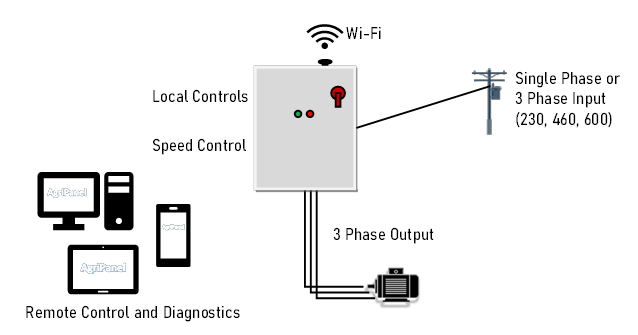

Example Usage: Farm C is challenged by the oversized motor on its dump pit, drag chain conveyor. They need to be very careful with their unloading rate, and the constant underutilization of it results in poor efficiency and a reduced power factor. Their AgriPanel Drive system gives them the precise speed and torque control needed to consistently get their ideal throughput. It also allows for increased flexibility in terms of unloading rate and dump pit grain levels, benefiting Farm A through increased throughput, improved efficiency, and less time spent digging out their dump pit.

Every AgriPanel comes with the following advantages:

- Ability to accommodate 230VAC, 480VAC, or 600VAC

- CSA certified panels built by a reputable controls and automation company

- The AgriPanel web interface, accessible from mobile devices or PCs on the same wireless network as the AgriPanel system

- Pre-programmed sequences to suit your farm, with the ability to easily add more as you see fit.

- Access to 24/7 support from trained IDS technicians, including remote monitoring and troubleshooting

Add-ons that can be added include:

- 3G/LTE Remote Control – access to AgriPanel web interface from anywhere

- Outdoor Installation – IDS can utilize enclosures/controllers designed to withstand temperature variations, rain, dust, and mud

- HMI Touchscreen mounted to panel

- Physical buttons, lights and dials as required

- Custom-built, single-phase service to three-phase voltage conversions

Kongskilde

IDS has worked with Kongskilde Industries equipment for over 30 years, gaining significant experience controlling and automating pneumatic conveyance systems in industrial settings. We now function as a full sales representative for Kongskilde equipment, while being able to pair our pair our controls and automation capabilities with them. Since 1949, Kongskilde Industries has been a pioneer in the field of pneumatic conveyance for a variety of materials. With systems that are efficient, gentle on material, and simple to move or disassemble, Kongskilde provides trusted solutions for the handling and cleaning of grain and seed. Want to learn more about Kongskilde offerings, and how IDS can pair our controls expertise with them to suit your needs? Reach out to agsales@idscontrols.com and we will be happy to assist you!